총 3 개의 제품이 검색되었습니다.

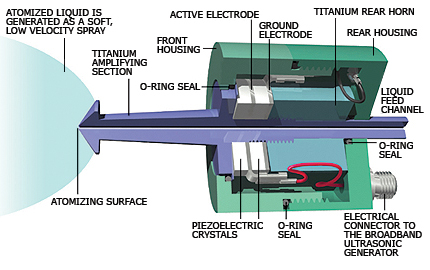

ULTRASONIC ATOMIZATION - Using high-frequency sound vibrations, ultrasonic nozzles create a soft spray without bounceback from the substrate, unlike pressure nozzles. When combined with low-pressure air (typically 1 psi), the atomized spray can be shaped in a variety of fan-shaped or conical spray patterns. The type of air shaping method used is dictated by the specific needs of each process. Capability to coat unlimited widths with multiple nozzle systems.

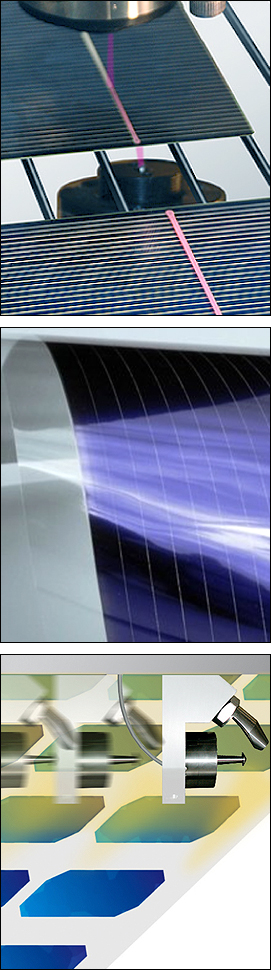

Sono-Tek offers ultrasonic coating equipment for wet processing of both thin film (flexible and non-flexible, including CIGs solar cells, CdTe solar cells and CZTs based solar cells) and silicon solar cell manufacturing. Sono-Tek coating systems offer significant cost savings over conventional vapor deposition processing in many solar cell coating applications.

Selective fluxing of solder bus lines on photovoltaic Si cells

Precise, targeted deposition and controlled velocity of the flux spray confines the flux to solder bus areas without overspray onto other areas of the cell. The ultrasonic vibration of the SelectaFlux nozzle makes it impossible for the nozzle to clogg, with only a monthly cleaning recommended. The SelectaFlux system is easily installed on existing Tabber Stringer lines.

Nanocoatings onto thin film solar cells

Sono-Tek ultrasonic coating systems are ideal for R&D applications spraying thin film nanosuspensions for active layers, TCO coating, PEDOT and anti-reflection layers, silver nanowire deposition, buffer layers (absorber layers) and quantum dots. The ultrasonic vibration of the nozzle breaks apart agglomerated particles (a common problem with nanosuspensions), creating highly uniform coatings from several microns to nanolayer thicknesses. Systems are available for both high temp and low temp processes and ultrasonic spray pyrolysis techniques.

Sono-Tek nozzles are also proven effective for spraying uniform coatings of carbon nanotubes, and are particularly effective in breaking apart agglomerations for the highest degree of uniformity and desirable coating morphologies for CNT coatings.

Examples of solutions sprayed onto flexible and non-flexible base substrates such as glass, stainless steel, conductive foils and other films:

Uniform coatings of liquid dopant solgel solutions, phosphoric acid solutions, titanium and zinc oxides for N-type and P-type silicon wafers

Sono-Tek offers several options for scalable doping processes, from fully enclosed R&D systems such as the ExactaCoat SC to inline systems such as our HyperSonic high speed reciprocating system for continuous high volume production. Advantages over traditional POCl3 batch doping processes:

Anti-reflection coatings for reducing surface reflection and maximizing cell efficicency

Sono-Tek ultrasonic nozzles are used to apply thin film and nanocoatings such as Silicon Monoxide (SiO) to reduce surface reflection and increase cell efficiencies.

1