총 3 개의 제품이 검색되었습니다.

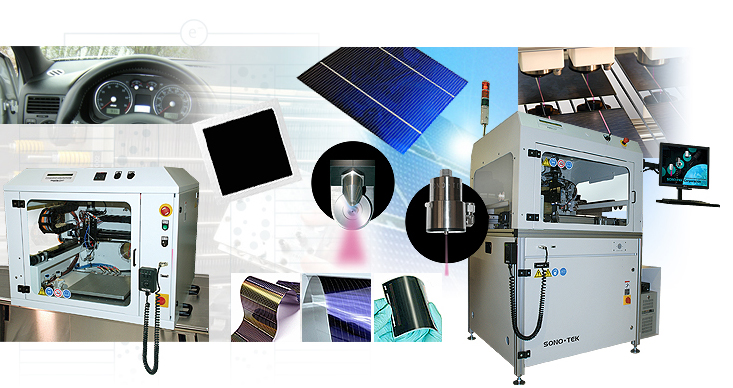

Sono-Tek is continually expanding our technology offerings in advanced energy applications, with large and small scale solutions installed at some of the largest solar cell and fuel cell manufacturers in the world. Some specific technology areas for solar cell manufacturing include solder bus fluxing of silicon solar cells, depositing suspensions for TCO layers in thin film solar cell manufacturing, phosphoric doping and spray pyrolysis applications. Fuel cell coatings for the production of PEMs include deposition of catalyst inks such as carbon black and other precious metal suspensions onto nafion membranes. Our ultrasonic technology offers uniform thin film nanocoatings that are highly durable and maximize efficiency with minimal overspray of expensive inks. We are excited to play a part in the advancement of solar cell and fuel cell development, enabling manufacturers to develop next generation products for these green technologies.

Click here for a recent article appearing in Global Solar Technology (p.26) discussing Sono-Tek's atomization systems for wet processing of nanoparticles in the solar cell and fuel cell manufacturing industries

1