The SelectaFlux Retrofit system is a complete, ready-to-integrate selective fluxing system.

Used in Tabber Stringer Machines for Fluxing the Solder Bus

Fluxing and soldering electrical contacts is a crucial process as it ensures that the connections between the silicon crystal and the conductive electrical contacts are optimal for electricity to flow between them properly. This process is key to ensuring the module's quality and longevity.

The SelectaFlux Retrofit ultrasonic fluxing system offers the highest degree of accuracy, precision, and fine line control in the industry.

Sono-Tek is one of the originators of spray fluxing technology. As the needs of the industry have changed, we have continued our commitment to leadership through state-of-the-art design and unsurpassed customer service.

Operating Principle

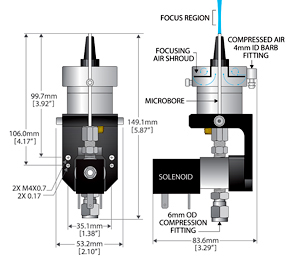

The SelectaFlux Retrofit system is a complete, ready-to-integrate selective fluxing system. It combines Sono-Tek's unique Microspray ultrasonic atomizing nozzle with low-pressure air to produce a controlled, highly focused beam of spray. A separate control module handles input/output system functions.

Compressed air, typically at 7 kPa (1 psi), is introduced into the diffusion chamber of the air shroud, which produces a uniformly distributed flow of air around the nozzle stem.

The ultrasonically produced spray at the tip of the stem is immediately entrained in the low pressure air stream. Spray width is controllable from 2 mm - 5 mm (0.080" - 0.20").

The spray envelope is bow-shaped. The width of the spray pattern is controlled by varying the distance between nozzle and substrate (from near-contact to approximately 2 inches).

SelectaFlux Retrofit Control Module

A compact, self-contained module consisting of flux control system; power supplies, ultrasonic broadband generator, electrical inputs and outputs, displays power, control of pressure to liquid delivery pressure reservoir, and pressure to air shroud.

The module contains a digital display for nozzle power and panel-mounted nozzle power, flow rate, and air pressure adjustments.

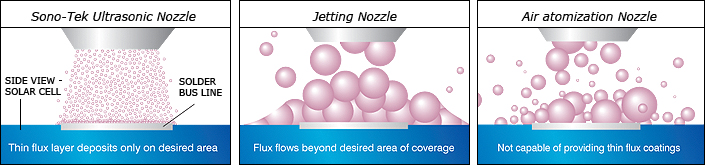

The Ultrasonic Advantage:

Compared to other Solar Cell fluxing methods, only Sono-Tek ultrasonic nozzles provide uniform, thin film coverage deposited only on target flux areas with minimal or no satellite flux droplets and no clogging.